When we usually choose valves, we usually use the following steps for selection:

01

To clarify the purpose of the valve

When choosing different types of valves, we first need to clarify what the valve is used for in the equipment or pipeline.

Then, it is necessary to determine the working status of the valve on the pipeline, the medium pipeline it is used in, the pressure of the pipeline where the valve is installed, whether it is a relatively stable pressure pipeline, or whether the pressure often fluctuates, and even some are high-pressure pipelines or vacuum systems; The internal temperature and ambient temperature of the system are also factors that must be considered. Factors such as valves of different materials and sealing materials will determine the minimum and maximum temperatures for valve use.

When selecting valves, it is important to correctly match valves that meet the technical requirements of the on-site pipeline, so that the pressure, temperature, and suitable medium of the valve match the on-site working conditions.

02

Determine the type of valve

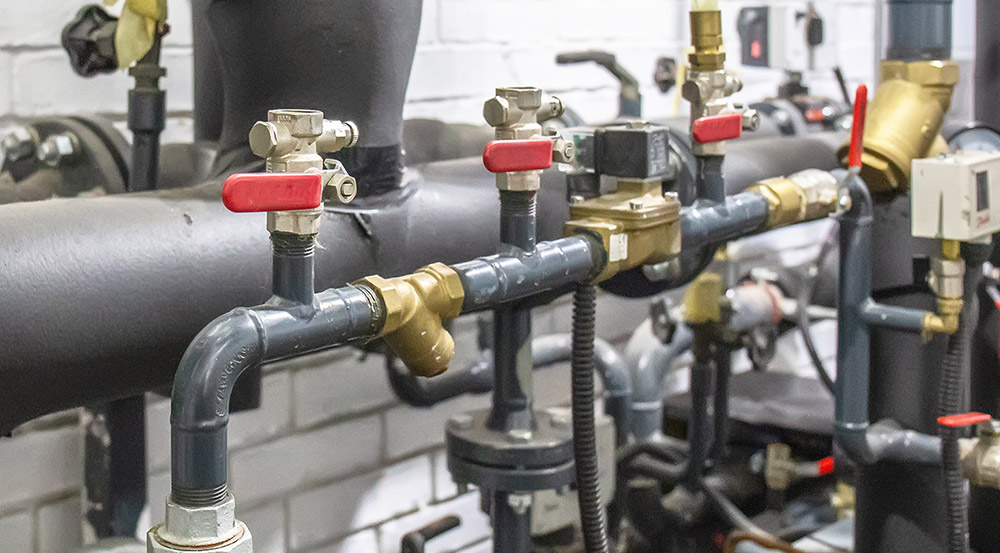

There are many types of valves on the market, and when choosing valves, we need to have a general understanding of the types of valves; For example, common on/off valves, regulating valves, safety valves, hydraulic control valves, special valves, and so on.

03

Determine the form of the valve

Based on the purpose and operating conditions of the valve, we need to determine the type of valve to be selected: gate valve, globe valve, ball valve, butterfly valve, plug valve, angle seat valve, pressure reducing valve, drain valve, plunger valve, regulating valve, safety valve, diaphragm valve, clamp valve, sludge valve, breathing valve, flame arrester, throttle valve, etc.

04

Determine the specific parameters of the valve

This step is very important. We need to determine the specific parameters of the valves to be installed on the pipeline to meet the requirements of the on-site working conditions. The parameters of a valve mainly include its nominal pressure, nominal diameter, etc. The specific parameters of the valve must match the installed pipeline.

In general, the standard system applied in the design of process pipelines is the basis for determining the application standards of other components of pressure pipelines. For example, when choosing a JB series standard flange, the matching valve must be selected as JB series standard, otherwise it cannot be installed correctly. After the pressure level of the pipeline is determined, our valve can determine the nominal pressure of the valve based on the pipeline pressure. For example, the nominal pressure of opening and closing a valve should be higher than the pipeline pressure level. The nominal diameter of the valve is also matched with the matching pipeline flange or joint.

05

Determine the material of the valve

The material of the valve body, components, and sealing surfaces is determined based on the medium, working pressure, and working temperature of the process pipeline. Such as brass valves, cast iron valves, stainless steel valves, carbon steel valves, forged steel valves, alloy steel valves, lined valves, and so on.

06

Determine the geometric parameters of the valve

After determining what material and model of valve to use, we can determine the geometric parameters of the valve based on its nominal diameter; For example, determining the structural length of the valve, the flange connection form and size, the height of the valve during opening and closing, the size parameters of the connecting bolt holes, and the overall dimensions of the valve.

Through the selection of the above steps, we can reasonably determine the valves required for on-site pipelines, and then proceed with valve procurement, valve installation, and other work. For beginners in daily valve selection, they may find valve knowledge difficult to learn all at once, or they may not know how to make the right choice for fear of making mistakes and dare not choose freely; So, we need to consult a professional valve manufacturer.