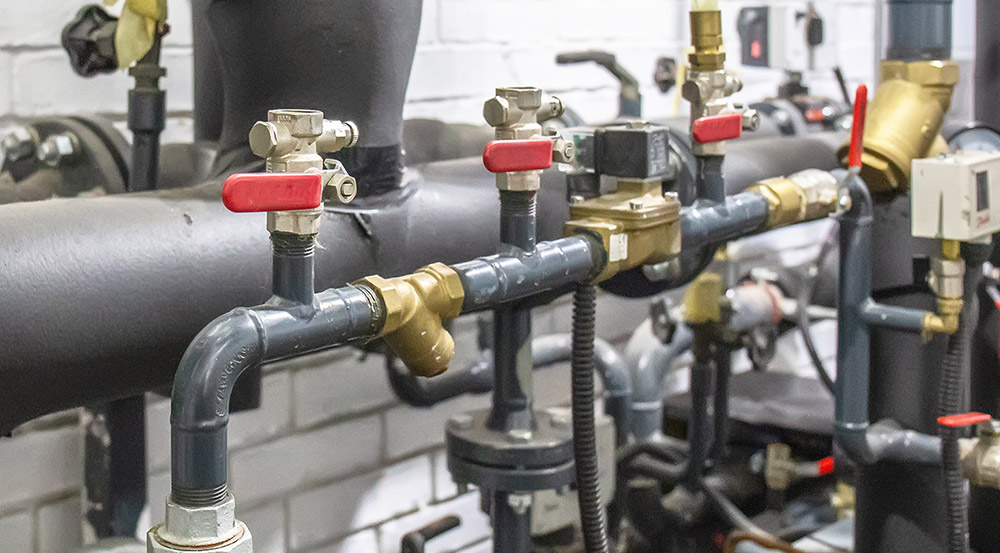

The structural principle of ball valves is to cut off or connect the medium in the pipeline, while multi way ball valves are used to distribute the medium and change the flow direction of the medium. Compared with other types of valves, ball valves have the following advantages.

1. The fluid resistance is small, the switch is fast, and convenient. As long as the valve stem rotates 90 °, the ball valve can complete the full open or full close action, making it easy to achieve rapid opening and closing.

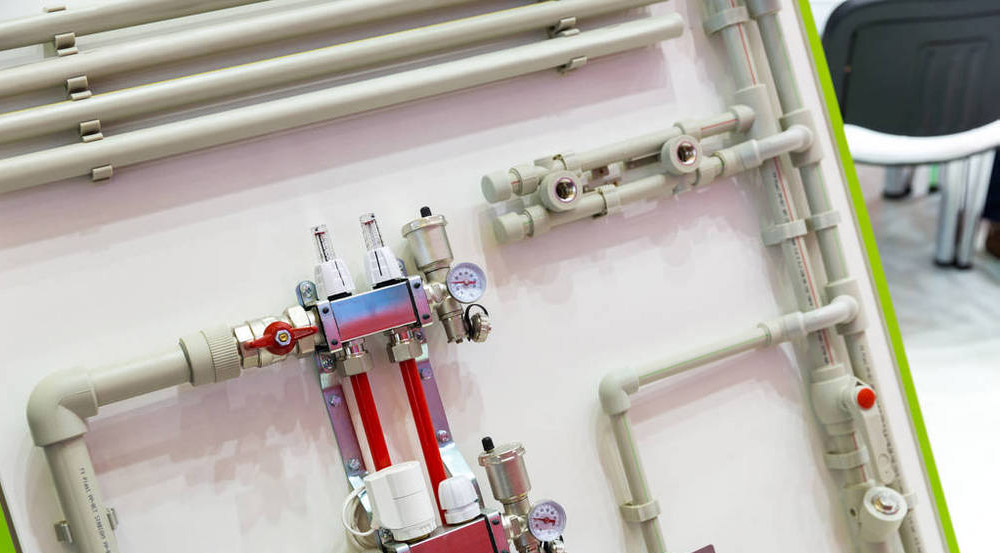

2. The valve seat has good sealing performance. The sealing ring is made of elastic materials such as polytetrafluoroethylene and PPL. The soft sealing structure is easy to ensure sealing, and the sealing force of the ball valve increases with the increase of medium pressure.

3. The valve stem seal is reliable. When the ball valve is opened and closed, the valve stem only rotates without lifting. The packing seal of the valve stem is not easily damaged, and the sealing force of the valve stem reverse seal increases with the increase of medium pressure.

4. Due to the excellent self-lubricating properties of materials such as polytetrafluoroethylene, the friction and wear with the ball are small, resulting in a long service life of ball valves.

5. Multiple driving mechanisms such as pneumatic, electric, and hydraulic can be configured to achieve remote control and automated operation.

6. The channel inside the valve body is smooth and can transport viscous fluids, slurries, and solid particles. 7. The use of metal seals has excellent sealing performance under high temperature and high pressure conditions.

Working principle of float valve

The float must always float on the water, and when the water rises, the float also rises. When the float rises, it drives the connecting rod to also rise. The connecting rod is connected to the valve at the other end, and when it rises to a certain position, the connecting rod supports a rubber piston pad, sealing the water…